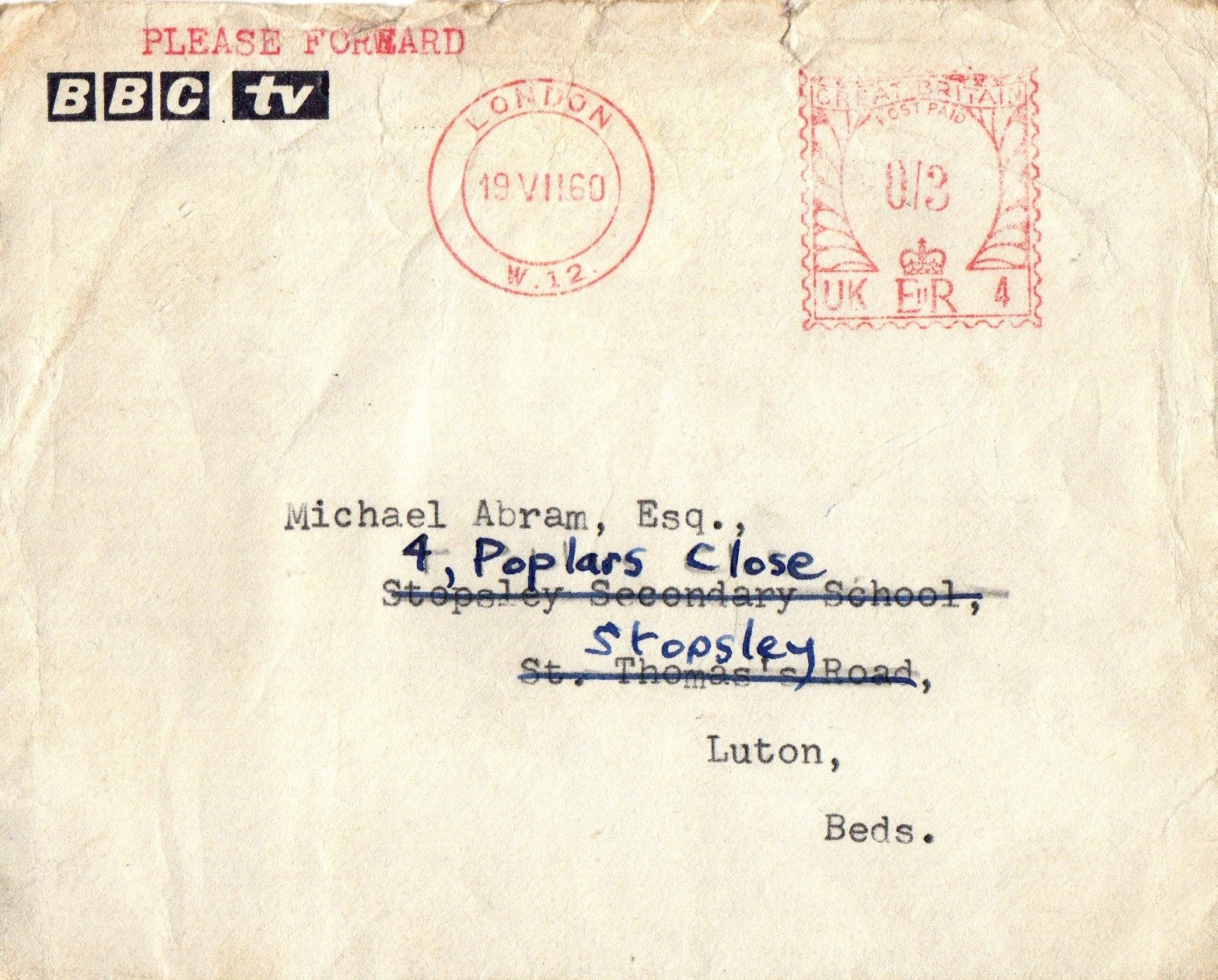

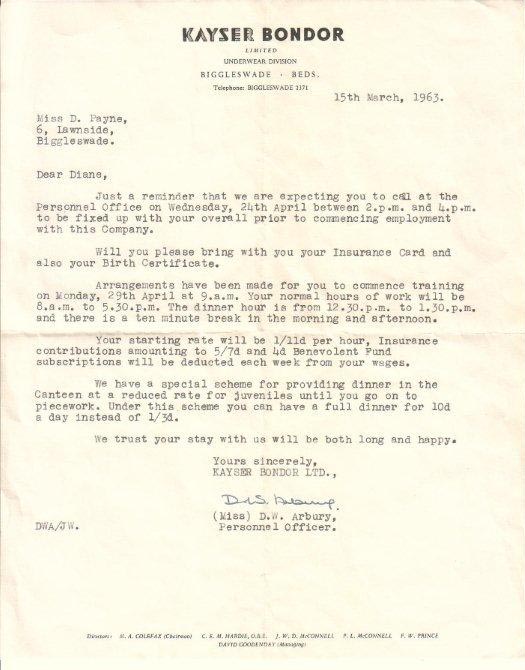

Charles Clay and Sons was established in 1861 by Charles Clay. An advertisement from the time records the company as inventors and patentees of the ‘low cost’ ribbon process which superseded the old method of weaving ribbons on a shuttle loom. The company had factories at Manchester, Cheapside, North Shields and Luton, where on leaving school in 1960, my dad had his first job as a trainee toolmaker.

By this time Charles Clay and Sons were now making more than ribbons. Situated on the ground floor and second floor, dad worked in the real leather department where banking items such as blotters, desk calendars and diaries were made, as well as plastic versions and other items such as tobacco stay fresh pouches, key rings and promotional gifts for companies such as BP and British Airways.

Dad was tasked with making and repairing high frequency (HF tools), setting up and repairing the HF welding machine, showing staff how to make new products, training the operators in safe loading of welding machines so as to not get HF burns to fingers and hands, organising stock arriving from the cutting room such as plastic sheet and cardboard. During his time there he also learnt to gold block and silk screen all the goods.

The first floor of the factory was offices and an in house printing press department, while the top floor was a machine sewing department making children’s shirts and ladies clothing. A small part of the factory housed ‘English Ribbons.’ Dad recalls that one of the women who worked there had previously worked as a conductress (also known as ‘clippy‘ because she would have ‘clipped‘ used tickets to prevent them being re-used) on London buses. One of her drivers had been the singer Matt Munroe.