During world war two, my grandmother, Delia Eileen Abram (nee Clarke) worked at Sywell Aerodrome in Northamptonshire, repairing the Irish linen skin covering on the bodywork of Wellington bombers.

The aerodrome dates back to 1927 when local landowner, Mr Harold Brown agreed to let 55 acres of his land off the Holcot Lane, adjacent the Belman Gate, to the Northamptonshire Aero Club. Today it has evolved from a world war two RAF facility into general aviation airfields.

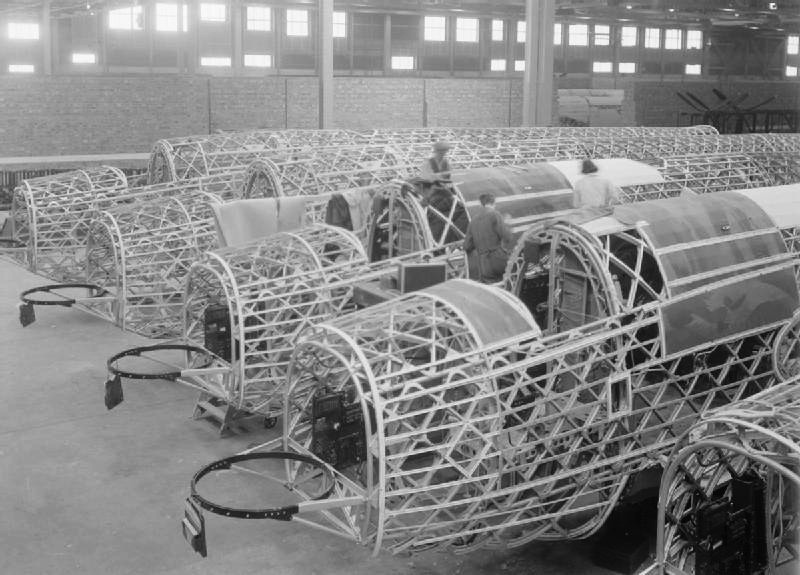

During the second world war activities at Sywell included the expansion of flying training, repairs to 1,841 of the RAF’s Wellington bombers and completion and flight testing of some 100 Lancaster mark two, four engined bombers. Brooklands Aviation Ltd oversaw the use of the ‘shadow factory scheme’ and saw two major sites used for aircraft overhaul and maintenance.

- Site number one concentrated on Wellington repair and Lancaster construction.

- Site number two site was based at Buttocks Booth in Moulton mainly for Wellington work.

Wellington Bombers flying in formation.

Wellington Bombers flying in formation.

Other local engineering shops and businesses were subcontracted to undertake specific component repair too, including Earl’s Barton Motors (Abram’s garage) which was run by my great grandfather Joseph Charles Abram. A document from the Harrington Museum states:

‘The number or aircraft needing repair increased rapidly during 1940 and the accommodation at the main centre at Sywell was found to be inadequate. This together with the policy of dispersal and the benefit of taking work to the people instead of the reverse with consequent saving in travelling, led to premises being requisitioned including Abram’s Garage, Earls Barton – used for undercarriage and bomb beams.’

The full document can be viewed below.

Second World War recruitment poster.

Around 2,000 people worked for Brooklands either directly or indirectly during world war two. However, as the men were conscripted, much of the work fell to women to undertake, including driving the roof cranes that shifted wings and tail fins into position, installing electrics and stitching a planes linen carapace.

The women who recovered and stitched the linen on airframes were nicknamed ‘Dope Judies’. The word dope referred to the layers of dope that formed the outer skin of the aircraft that the Irish linen was treated with.

Flight Mechanic website explains:

‘Fabric-covered aircraft play an important role in the history of aviation. The famous Wright Flyer utilized a fabric-covered wood frame in its design, and fabric covering continued to be used by many aircraft designers and builders during the early decades of production aircraft. The use of fabric covering on an aircraft offers one primary advantage: light weight. In contrast, fabric coverings have two disadvantages: flammability and lack of durability.Finely woven organic fabrics, such as Irish linen and cotton, were the original fabrics used for covering airframes, but their tendency to sag left the aircraft structure exposed to the elements. To counter this problem, builders began coating the fabrics with oils and varnishes. In 1916, a mixture of cellulose dissolved in nitric acid, called nitrate dope, came into use as an aircraft fabric coating. Nitrate dope protected the fabric, adhered to it well, and tautened it over the airframe. It also gave the fabric a smooth, durable finish when dried.’

Wellington bombers under construction, showing the airframe.

Stitching tightly with a curved needle, at a regulation eight stitches per inch, so the wind could not rip the seams open, the mostly female workforce worked 12 hour shifts, six days a week, in damp unheated hangars.

Sources

- Sywell Aviation Museum

- A short history of Brookland Aviation Ltd at Sywell

- Did Sywell help in developing the Dambusters bouncing bomb

- Flight Mechanic